|

A typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. The only addition operation needed is the removal of a slight burr. The process requires a triple-action fine-blanking press. Closing force, counterpressure, and blanking pressure forces are individually and infinitely adjustable.

How Fineblanking Works:

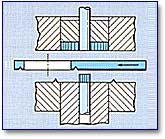

This represents a simple sliding punch fineblanking tool making a round washer with a hole at its center.

This represents a simple sliding punch fineblanking tool making a round washer with a hole at its center.

|

|

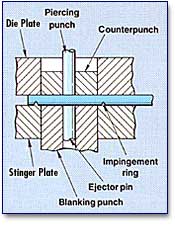

1. The tool closes, pressure

embeds impingement ring into stock. This prevents material from flowing away form the punch, ensuring a smooth, extruded edge on the part.

1. The tool closes, pressure

embeds impingement ring into stock. This prevents material from flowing away form the punch, ensuring a smooth, extruded edge on the part.

|

|

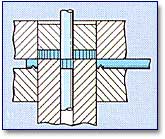

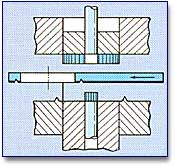

2. Blanking punch advances until part is fully sheared and resting in upper die opening. In the same action, the pierce

punch provides a hole in the workpiece. Simultaneously, counter punch pressure holds part firmly against face of

the advancing blanking punch. This maintains flatness and enhances the sheared edge, eliminating diebreak or

edge fracture.

2. Blanking punch advances until part is fully sheared and resting in upper die opening. In the same action, the pierce

punch provides a hole in the workpiece. Simultaneously, counter punch pressure holds part firmly against face of

the advancing blanking punch. This maintains flatness and enhances the sheared edge, eliminating diebreak or

edge fracture.

|

|

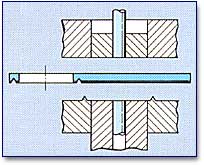

3. All forces are relaxed, and the tool starts to open. The ram descends by gravity.

3. All forces are relaxed, and the tool starts to open. The ram descends by gravity.

|

|

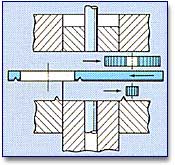

4. Blanking pressure reverses, the punch pulls back and the ejector pin pushes out slug. Simultaneously, raw material

advances for the next cycle.

4. Blanking pressure reverses, the punch pulls back and the ejector pin pushes out slug. Simultaneously, raw material

advances for the next cycle.

|

|

5. Counter pressure is reapplied, pushing part out of the die opening.

5. Counter pressure is reapplied, pushing part out of the die opening.

|

|

6. Air blasts or mechanical sweeps remove part and slug from die area.

6. Air blasts or mechanical sweeps remove part and slug from die area.

|

|

7. The system is ready to start the next cycle.

7. The system is ready to start the next cycle.

|

|

Click here to see animation.

animation requires Flash player [download

player]

|